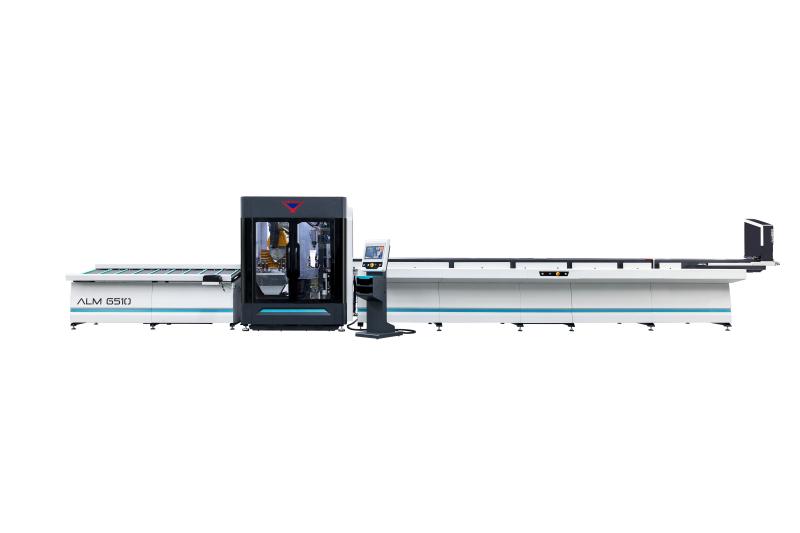

YILMAZ MAKİNE SAN VE TİC AŞ

Founded in 1977, Yılmaz Machine manufactures PVC and Aluminium Profile Processing Machines. It was established to meet the needs of Production, Installation, Technical Service & Maintenance and Spare Parts. Yılmaz Machine continues its sales and production activities in different continents and countries. With an export volume of more than 100 countries around the world, it has a dealer network of over 120 worldwide. Yılmaz Machine has adopted the principle of development, using the technologies of its solution partners in the fields of mechatronics, pneumatics, and hydraulic hydropneumatic and providing services in the fields of research, development, design, production, sales, and after-sales to meet changing needs. Considering the sectoral, social, and individual interests with the rapid growth it provides, Yılmaz Machine invests in the increase of its country, sector, and production volume.